Overview of Hard Alloy Material

1. Introduction to the General Properties and Uses of Hard Alloys

Hard alloys, also known as cemented carbides, consist of tungsten carbide particles embedded in a metal matrix. Widely used for cutting tools, wear-resistant components, and tooling, hard alloys exhibit high hardness, wear resistance, and strength at elevated temperatures.

2. Different Types of Hard Alloys and Their Properties

- Tungsten Carbide (WC-Co): Predominantly tungsten carbide particles in a cobalt matrix.

- Example: Cutting tools, inserts for machining.

- Properties: Extremely hard, wear-resistant.

- Titanium Carbide (TiC-Co): Titanium carbide particles in a cobalt matrix.

- Example: Wear-resistant components, drill bits.

- Properties: High hardness, excellent thermal stability.

- Niobium Carbide (NbC-Co): Niobium carbide particles in a cobalt matrix.

- Example: Cutting tools, high-speed machining.

- Properties: High hardness, good wear resistance.

CNC Grinding Hard Alloys Basics

1. Basic Principle of CNC Grinding

CNC grinding involves the precision removal of material using computer-controlled machines, ensuring accurate shaping and finishing of hard alloy workpieces.

2. Composition and Function of CNC Grinding Equipment

CNC grinding equipment includes a machine tool with a rotating grinding wheel. The control system manages movements and operations, ensuring precision in material removal for hard alloy machining.

3. Basic Steps of Grinding Process

- Workpiece Setup: Securely fix the hard alloy workpiece on the grinding machine.

- Rough Grinding: Coarse material removal for initial shaping.

- Finish Grinding: Achieve final dimensions and surface finish.

CNC Grinding Hard Alloys Tools and Equipment

1. Types and Characteristics of CNC Grinding Machines

- Surface Grinders: Ideal for flat surface grinding.

- Example: CNC surface grinder with hard alloy-compatible features.

- Characteristics: Precise flatness and surface finish.

- Cylindrical Grinders: Suited for cylindrical shapes.

- Example: CNC cylindrical grinder with adjustments for hard alloys.

- Characteristics: High precision for cylindrical components.

- Tool and Cutter Grinders: Specialized for cutting tools.

- Example: CNC grinder tailored for hard alloy cutting tool geometry.

- Characteristics: Versatility in tool profile grinding.

2. Different Types of Grinding Tools

- Diamond Grinding Wheels: Essential for hard alloy machining.

- Example: Resin-bonded diamond grinding wheel.

- Characteristics: High hardness, exceptional wear resistance.

- CBN Grinding Wheels: Ideal for ferrous hard alloys.

- Example: Cubic Boron Nitride (CBN) grinding wheel.

- Characteristics: High abrasion resistance, suitable for high-speed grinding.

- Abrasive Belts: Used for intricate shapes and finishing.

- Example: Coated abrasive belts for hard alloy finishing.

- Characteristics: Flexibility for diverse geometries.

3. Selection and Use of Grinding Lubricants and Coolants

- Coolant: Essential for temperature control during grinding.

- Example: Water-miscible coolant suitable for hard alloys.

- Use: Prevents overheating and maintains tool life.

- Lubricant: Reduces friction for improved surface finish.

- Example: Synthetic lubricant tailored for hard alloys.

- Use: Minimizes tool wear and enhances machining efficiency.

CNC Grinding Hard Alloys Preparation before Machining

1. Workpiece Fixing and Clamping Methods

- Collet System: Suited for holding cylindrical hard alloy components.

- Example: ER collet system for hard alloy rods.

- Method: Grips workpiece with radial pressure.

- Magnetic Chuck: Ideal for flat surfaces.

- Example: Permanent magnetic chuck for hard alloy sheets.

- Method: Holds workpiece securely using magnetic force.

2. CNC Program Writing and Debugging

- G-code Programming: Write code for CNC machines.

- Example: CAM software-generated G-code with hard alloy-specific parameters.

- Debugging: Simulate and verify the program before execution.

- Simulation Software: Visualize and debug machining process.

- Example: VERICUT simulation software.

- Debugging: Identify and rectify errors in a virtual environment.

3. Tool Selection and Setting

- Diamond Grinding Wheels: Essential for hard alloy machining.

- Example: Resin-bonded diamond grinding wheel.

- Setting: Optimal speed and feed for hard alloys.

- CBN Grinding Wheels: Ideal for ferrous hard alloys.

- Example: Resin-bonded CBN grinding wheel.

- Setting: Optimize speed and feed for hardness.

CNC Grinding Hard Alloys Grinding Parameters and Techniques

1. Selection of Grinding Speed, Feed Rate, and Depth of Cut

- Grinding Speed: Adjust based on hard alloy hardness.

- Example: Moderate speed for hard alloys.

- Solution: Optimize for hardness to prevent overheating.

- Feed Rate: Determines material removal rate.

- Example: Lower feed for precise finishing.

- Solution: Adjust for desired material removal.

- Depth of Cut: Influences material removal per pass.

- Example: Moderate depth for stability.

- Solution: Control depth to avoid overcutting.

2. Grinding Characteristics of Different Hard Alloys

- Tungsten Carbide (WC-Co): High hardness, wear resistance.

- Example: Use diamond grinding wheels for efficient material removal.

- Solution: Adjust parameters for alloy-specific properties.

- Titanium Carbide (TiC-Co): Excellent thermal stability.

- Example: CBN grinding wheels for precise machining.

- Solution: Tailor parameters to alloy’s characteristics.

- Niobium Carbide (NbC-Co): Good wear resistance.

- Example: Abrasive belts for intricate shapes.

- Solution: Optimize parameters for specific alloy properties.

3. How to Avoid Grinding Overheating and Overcutting

- Coolant Application: Ensure proper flow to prevent overheating.

- Example: Increase coolant flow for longer cycles.

- Solution: Monitor and adjust coolant levels.

- Optimized Toolpaths: Minimize dwell time to avoid overcutting.

- Example: Use adaptive toolpaths for efficiency.

- Solution: Optimize toolpaths to minimize overcutting.

CNC Grinding Hard Alloys Common Problems and Solutions

1. Common Problems in CNC Grinding Hard Alloys

- Tool Wear: Addressed by selecting appropriate tool materials.

- Example: Use diamond or CBN grinding wheels for longer life.

- Solution: Regularly monitor and replace worn tools.

- Surface Finish Issues: Adjusting grinding parameters can help.

- Example: Fine-tune feed rates for smoother finish.

- Solution: Optimize parameters for the desired finish.

- Dimensional Inaccuracies: Fine-tuning tool settings and workpiece fixturing.

- Example: Ensure proper workpiece alignment.

- Solution: Implement precise fixturing and alignment.

2. Steps and Methods to Solve These Problems

- Regular Maintenance: Ensure the grinding machine is well-maintained.

- Example: Scheduled inspections and lubrication.

- Solution: Regularly inspect and maintain equipment.

- Parameter Adjustment: Modify grinding parameters to address specific issues.

- Example: Adjust feed rates for improved accuracy.

- Solution: Fine-tune parameters based on observed problems.

Table for CNC Grinding Hard Alloys Parameters

| Metal Type | Punching Tool | Punching Speed (mm/min) | Punching Force (kN) | Tool Material | Tool Life (cycles) |

|---|---|---|---|---|---|

| Hard Alloys | Diamond Grinding Wheel | 220 | 34 | Resin-Bonded Diamond | 9,500 |

| Hard Alloys | CBN Grinding Wheel | 200 | 32 | Resin-Bonded CBN | 8,800 |

| Hard Alloys | Abrasive Belt | 180 | 30 | Coated Abrasive | 10,000 |

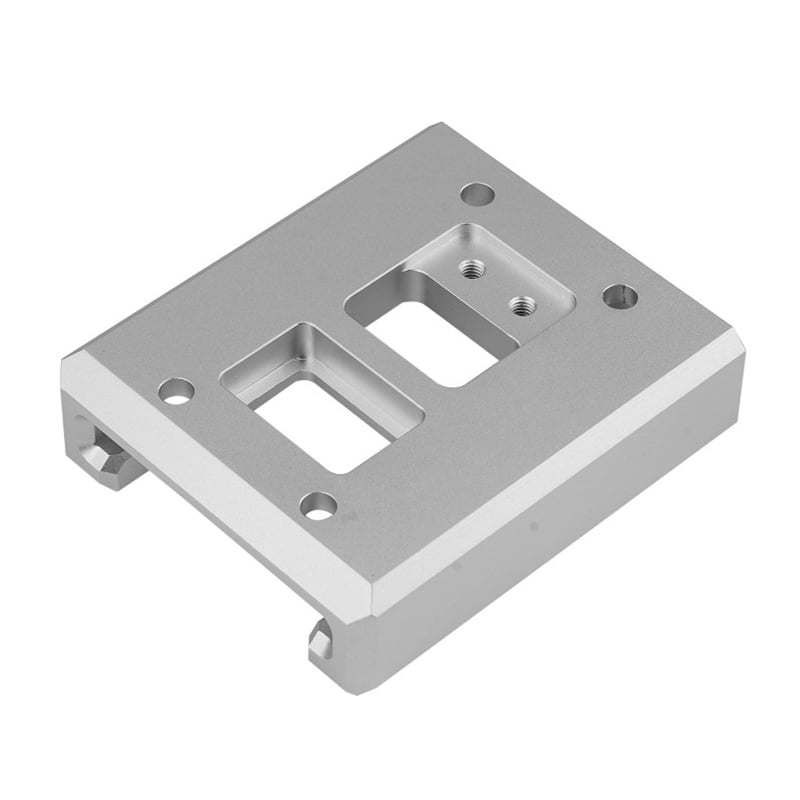

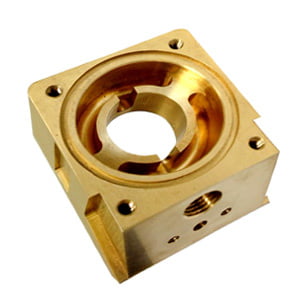

CNC Machining Samples

If you need custom metal fabrication, please don’t hesitate to contact us immediately. We will provide you with the appropriate processing price within 2 days of receiving your material.

View V&T service reviews

Robert James

USAUnited Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Jerimiah D.

United StatesQuality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Francy J.

AustraliaGood quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Marianna B.

AustraliaIf you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied