Choosing V&T Machining for your copper laser cutting needs means opting for precision, reduced warping, and metal purity. Our commitment to excellence, coupled with advanced techniques, positions us as leaders in providing tailored solutions for industries with exacting standards. Trust V&T Machining to master the intricacies of copper laser cutting and deliver results that exceed expectations.

Laser cutting has revolutionized the processing of various materials, but when it comes to copper, challenges arise that demand a specialized approach. At V&T Machining, we pride ourselves on employing cutting-edge tools and techniques to deliver precise copper laser cutting solutions tailored to diverse industries, including aerospace, automotive, and telecommunications.

V&T Machining offers you a complete guide to Laser Cutting Copper

| Copper Type | Cutting Tool | Cutting Speed (mm/min) | Laser Power (kW) (Thickness-Dependent) | Focus Lens Material | Focus Lens Life (hours) |

|---|---|---|---|---|---|

| Pure Copper (C11000) | CO2 or Fiber Laser | 600-900 | 2-4 (thickness-dependent) | ZnSe or Si | 300-500 |

| Copper Alloys (e.g., Brass – C26000) | CO2 or Fiber Laser | 800-1200 | 2-5 (thickness-dependent) | ZnSe or Si | 300-500 |

| Beryllium Copper (C17200) | CO2 or Fiber Laser | 500-800 | 2-4 (thickness-dependent) | ZnSe or Si | 300-500 |

| Phosphor Bronze (C51000) | CO2 or Fiber Laser | 600-1000 | 2-5 (thickness-dependent) | ZnSe or Si | 300-500 |

| Copper-Nickel Alloy (e.g., Cu-Ni 90/10 – C70600) | CO2 or Fiber Laser | 700-1100 | 2-5 (thickness-dependent) | ZnSe or Si | 300-500 |

Challenges in Copper Laser Cutting:

Unlike conventional materials, copper poses unique challenges due to its reflective nature. Traditional CO2 lasers with a wavelength of 10.6 µm struggle with copper, as it reflects rather than absorbs infrared laser light. However, at V&T Machining, we leverage lasers with shorter wavelengths, enabling us to penetrate copper effectively and achieve unparalleled precision. Success in copper laser cutting hinges on temperature control, angle optimization, cutting speed, and strategic gas utilization.

Technical Approach:

V&T Machining approaches complex copper laser cutting projects with meticulous care and unwavering commitment to quality assurance. Our proficiency in this field minimizes waste, reduces costs, and meets the exacting needs of clients in demanding sectors such as telecommunications and automotive manufacturing.

Optimizing Copper Cutting Speeds and Laser Positioning:

Our focus on cut speed and laser positioning is paramount in ensuring optimal results. By identifying the correct initial piercing point on the copper sheet, we maximize beam efficiency. Adjusting power settings and aligning the sheet grain minimizes drag, facilitating a clean and efficient cut. High-pressure oxygen is employed during copper laser cutting to enhance the consistency of the process, creating a copper oxide layer on the surface that reduces reflectivity, ensuring quicker and more predictable laser penetration.

Benefits of Copper Laser Cutting:

- Exceptional Precision: Copper’s exceptional conductivity makes it indispensable for intricate components in electronics. V&T Machining excels in providing laser-cut copper plates and wires with unparalleled precision, meeting the stringent requirements of sectors like telecommunications.

- Reduced Warping: Our copper laser cutting methodology minimizes the likelihood of warping, ensuring the final product remains flat and undamaged. V&T Machining’s expertise extends beyond cutting to proper cleaning, packaging, and shipping, guaranteeing the safety of the delivered components.

- Metal Purity: Advanced laser copper cutting at V&T Machining significantly reduces the risk of metal contamination. This is crucial for clients in sectors such as automotive and telecommunications, where the final product may undergo chemical treatments.

Our Laser cutting copper equipment

| Working Area | 1510×3050mm |

| Max Linkage Speed | 140m/min |

| Max Acceleration | 1.5G |

| Positional Accuracy | ±0.03mm |

| Re-positional Accuracy | ±0.02mm |

| Pipe Section Shape | Round/Square Tube/Rectangular |

| Tube Size Range (Dual Pneumatic) | T160:Round:Φ16-Φ155mm Square:□16-□155mm Rectangular:Long Side≤155mm T220: Round:Φ20-Φ220mm Square:□20-□220m Rectangular:Long Side≤220mm |

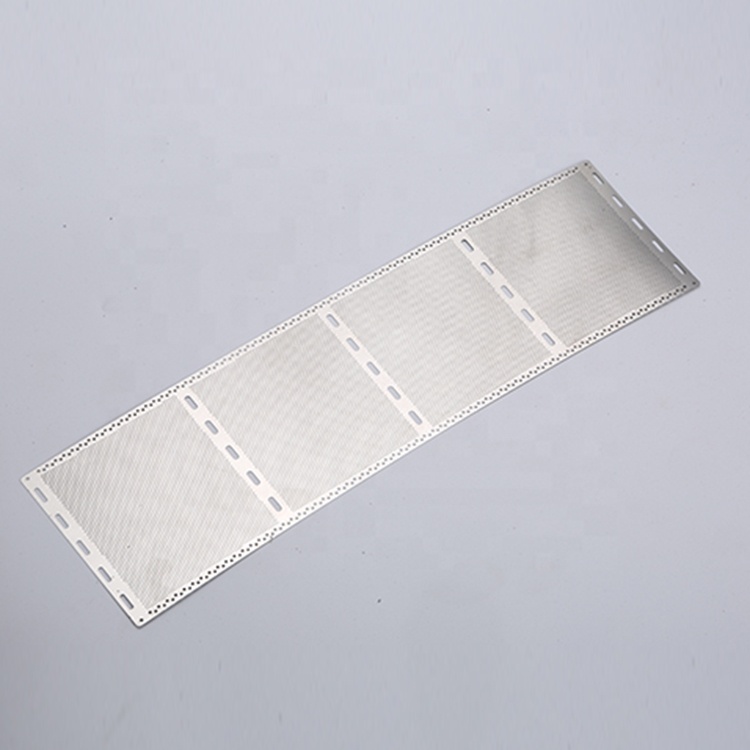

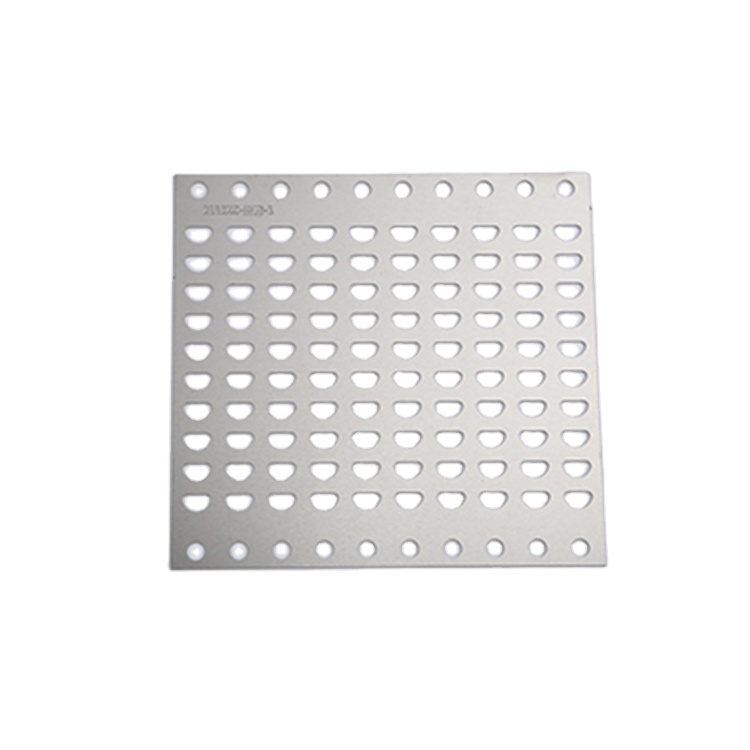

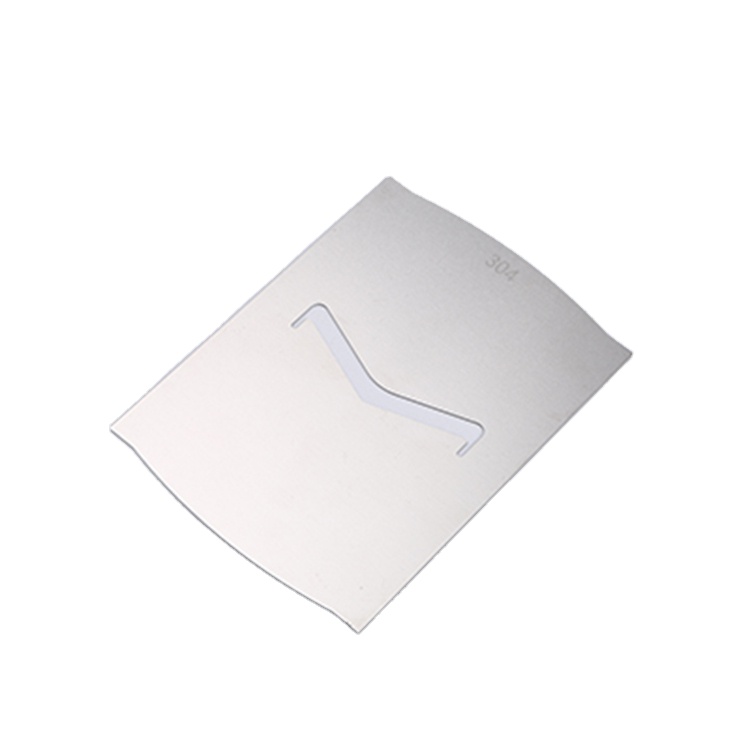

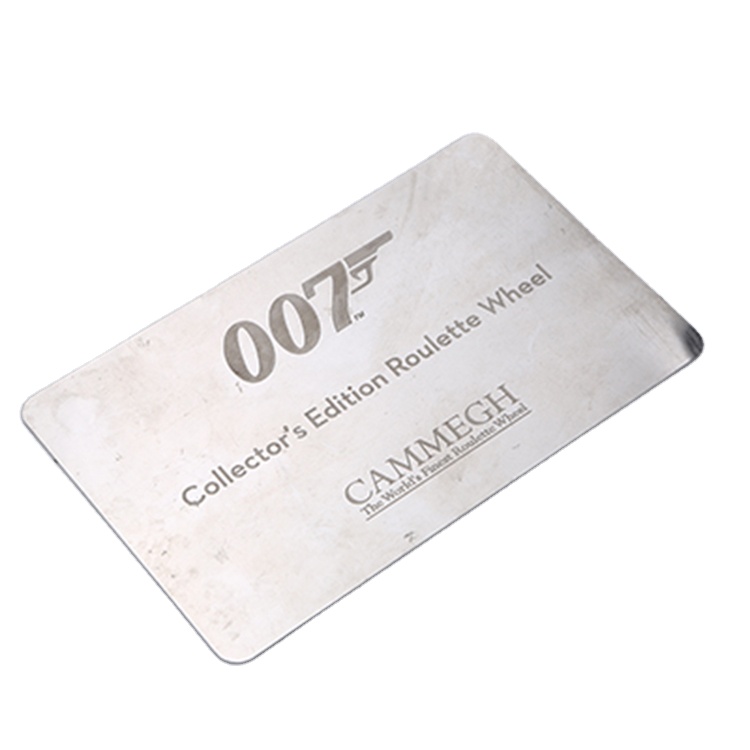

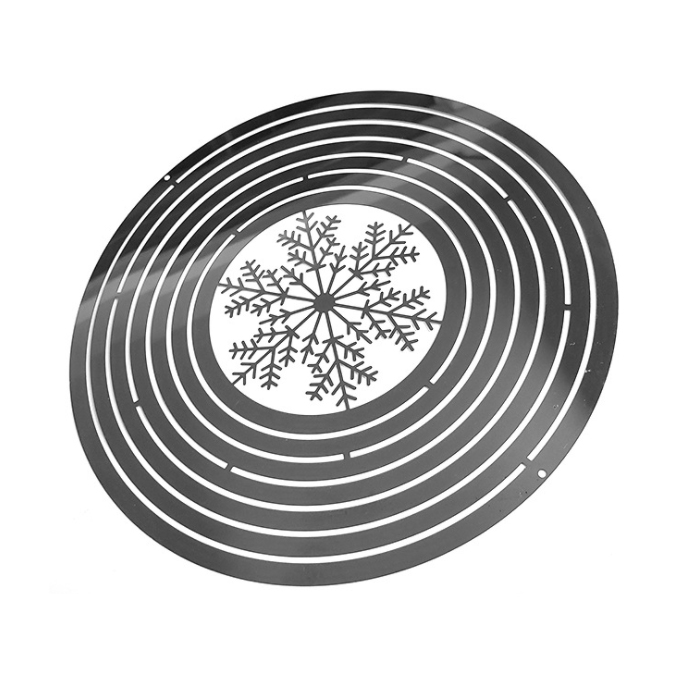

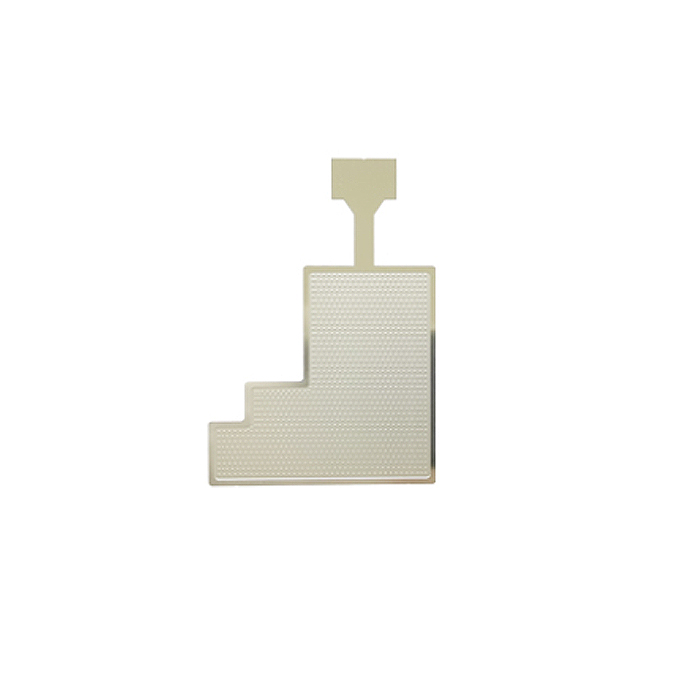

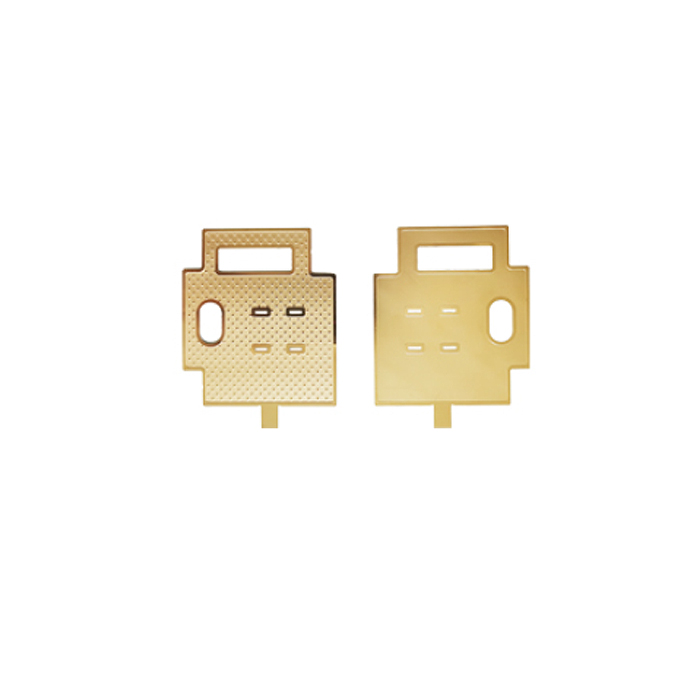

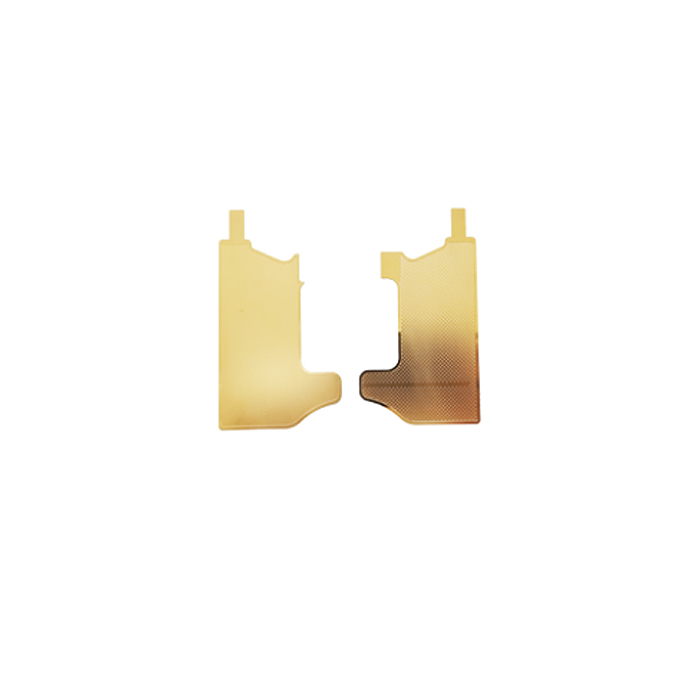

Laser Cutting Samples

FAQ

Do you have your own factory?

Yes, our factory is located in Shenzhen, China. We own a very professional team.

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

Are you experienced in different surface treatment?

Yes. We make surface treatment like: anodizing, nickel plating, electrolytic polishing, zinc plating, black oxide,TIN coating...

Are you experienced in different heat treatment?

Yes. We make heat treatment like: Nitriding, Quenching and tempering, Case Hardening, Carburize Hardening, Vacuum heat treatment

Do you make stock for your customers?

Yes in some cases we would make some stock for our customers.

Contact Us

If you need custom metal fabrication, please don’t hesitate to contact us immediately. We will provide you with the appropriate processing price within 2 days of receiving your material.

View V&T service reviews

United Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Robert James

United Statesthis company is my go to! have used them multiple times great prices V&T is the best to work with!

Robert James

Quality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Jerimiah D.

Quality yet cheap. Service Staff was very friendly and helpful. Measurements of parts was very accurate for the anodized aluminium, and prices were very competitive

Jerimiah D.

Good quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Francy J.

Good quality of the product, the color matches the photos. The milling machine operator is good. Thanks.

Francy J.

If you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied

Marianna B.

If you can deal with V&T you will have a very good experience. Sometimes they can be quite late though, and communication was bad for a while. I have dealt with this company for 3 years now. Mostly satisfied

Marianna B.